2022 KOREA SOURCING FAIR in Thailand

2022-09-28 ~ 2022-09-29Machinery & Parts Other Machinery

- Model Name

-

Specification

Size varies depending on the order.

- Color

-

Introduction

Quite widely utilized among metal processing industries such as of automobile parts, heatexchanger.

- Certification

-

Price

-

Buy Sample

|

Brazing Furnace |

|

|

Continuous

Brazing Furnace

Continuous brazing furnaces which have protective atmosphere composition are quite widely utilized among metal processing industries such as of automobile, home electric apparatus, heat-exchanger & pressurized receptacles etc.

Although those furnaces are said to be units suitable for mass production, depending upon relationship between temperature and time, atmosphere composition & characteristics of brazing filler metals, very cautions consideration and designing would be necessitated.

Sung Jin Heat Industry has been supplying excellent plants to the industries of various segments under our affluent experiences and business performance results.

In complex heat treatment, brazing shall have many varieties of potentials in future development.

It would be vital to make function of each part in continuous furnace match with treating process of work piece which was designed in consideration of elements as metal materials & machinery construction and to minimize consumable materials plus labour hours..

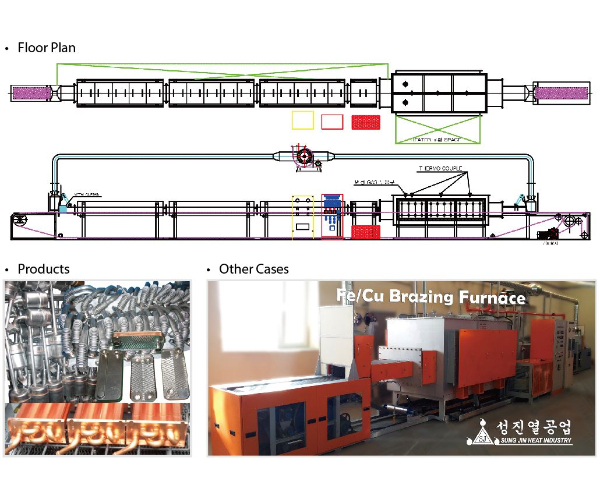

01. Fe/Cu Brazing Furnace (Energy

Saving Type)

An exothermic gas generator is required for brazing of ferrous or coppery alloys.

In the generator, the heating value produced on gas generation is cooled with enormous volume of water.

The generating chamber of the generator is built in the heating zone of heating furnace, where the heating value produced in gas generation is recycled to utilize for preheating to produce 35 to 50℃ of substantial save-energy effect.

1. 35 to 50% of save energy effect is attainable by utilizing the emitting heating value produced by gas generation for preheating of the heating zone.

2. Atmosphere in the heating furnace is stabilized.

3. Temperature distribution curve of heating furnace is logically available to fix.

4. High productivity is possible to attain by continuous process.

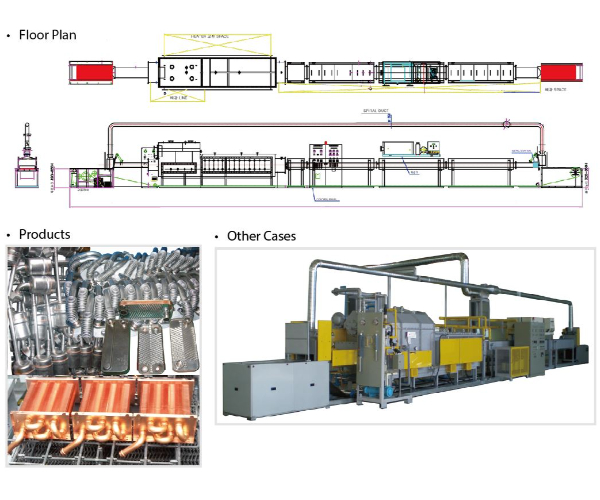

02. SUS Brazing Furnace (Hump

Type)

This unit is widely used for brazing of stainless steel, iron under gas atmosphere or several metals which need treatment under strong-reducing atmosphere and also for bring annealing.

1. The durability of Mesh-Belts was increased by applying Ceramic Skid Rail to the bottom of the muffler.

2. Atmosphere in heating & cooling sectors is being stabilized.

3. Temperature profile could reasonably be determined.

4. Productivity shall be higher in continuous treatment.

5. In case atmosphere is expensive and light in specific gravity as hydrogen, this method shall preferably be employed to make the operation more economical.

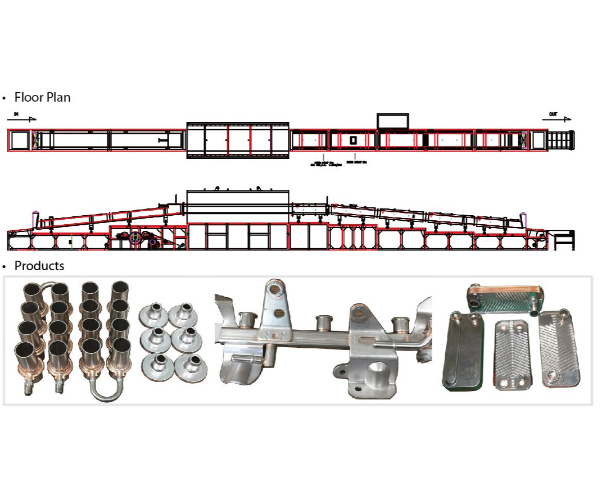

03. Fe/Cu Brazing Furnace

(Standard Type)

This unit is widely used for iron or copper brazing under gas atmosphere and also for bright annealing.

1. Atmosphere in heating & cooling sectors is being stabilized.

2. Temperature profile could reasonably be determined.

3. Productivity shall be higher in continuous treatment.

4. In the event for charging height of workpiece being higher, this method consumes fewer volume of atmosphere and treatment would be done more economically & precisely.

| Category | Main Item |

|---|---|

|

|

| CEO | CHANG SOO MOON |

|---|---|

| Foundation Year | - |

| Annual sales(per year) | - |

| Employees | - |

| Homepage | www.sungjinro.com |

| Address | (18633) 경기 화성시 양감면 은행나무로 194-5 성진열공업 |

| Company Introduction |

Buyers

Buyers Sellers

Sellers